How GRP Grating Reduces Maintenance Costs in the Long Run

Introduction

In industrial, commercial, and even residential environments, material selection plays a central role in determining long-term performance, safety, and cost efficiency. While traditional materials like steel and wood have been used for decades, they often bring challenges such as corrosion, frequent maintenance, heavy weight, and limited durability. This is where GRP Grating proves to be a superior alternative.

As industries seek ways to reduce operational expenses and improve structural longevity, GRP Grating has emerged as a preferred solution. Its unique combination of strength, corrosion resistance, and low maintenance requirements makes it remarkably cost-effective over time. This article explores in detail how GRP Grating minimizes maintenance costs in the long run, making it an intelligent investment for modern infrastructure.

Understanding GRP Grating

Before exploring its cost-saving benefits, it is essential to understand what GRP Grating is and why it is such a popular choice.

What Is GRP Grating?

GRP Grating (Glass Reinforced Plastic Grating) is a composite product made of fiberglass reinforced with resin. It is engineered through molding or pultrusion to create a lightweight yet incredibly strong structural panel.

Why GRP Grating Stands Out

- High strength-to-weight ratio

- Excellent corrosion resistance

- No need for painting or coating

- Non-conductive

- Fire-retardant properties

- Long service life These characteristics not only improve safety and performance but greatly reduce the ongoing costs of ownership.

How GRP Grating Reduces Maintenance Costs Over Time

The primary factor that draws buyers toward GRP Grating is its long-term economic value. Below are the main ways in which it significantly lowers maintenance requirements and costs.

1. Superior Corrosion Resistance = Zero Rust-Related Repair Costs

Corrosion is one of the most expensive maintenance issues in environments exposed to moisture, chemicals, and harsh weather. Traditional steel grating quickly deteriorates, requiring repainting, galvanizing, or full replacement.

Why GRP Grating Performs Better

GRP Grating is naturally corrosion-resistant because it contains no metal. Its fiberglass-reinforced composition withstands:

- Chemical splashes

- Saltwater

- Acids and alkalis

- Humid or marine environments

This eliminates common maintenance tasks such as:

- Rust removal

- Anti-corrosion coatings

- Corrosion-based component replacements

GRP Grating ensures consistent performance without the costly upkeep typically associated with steel.

2. Minimal Structural Deterioration Extends Service Life

Traditional materials degrade over time, especially in demanding industrial environments. Wood rots, steel corrodes, and aluminum warps under high heat.

Long-Term Stability of GRP Grating

Because GRP Grating is designed to be chemically and environmentally stable, it does not weaken easily. Its structural integrity remains strong for decades with minimal intervention.

This extended lifespan means fewer replacements, reduced labor costs, and less operational downtime — all of which lead to substantial cost savings.

3. No Need for Repainting or Surface Treatment

One of the most expensive recurring tasks in industrial maintenance is applying protective coatings. Steel and wood gratings require regular painting to avoid corrosion, fading, or degradation.

GRP Grating Maintains Its Finish

The color in GRP Grating is integrated during manufacturing, not applied afterward. This means the color does not peel, fade, or require refreshing.

Benefits include:

- No repainting expenses

- No shutdowns for coating maintenance

- A permanently attractive appearance without effort

This single detail saves thousands in maintenance costs over the lifespan of the installation.

4. Lightweight Composition Reduces Handling and Installation Costs

Maintenance costs are not just about what happens after installation — they also include labor and equipment requirements for handling materials.

GRP Grating Is Much Easier to Work With

Because GRP Grating is significantly lighter than steel, it can be:

- Lifted by fewer workers

- Installed without heavy machinery

- Easily removed and replaced for cleaning or repairs

This results in:

- Lower installation labor costs

- Faster maintenance procedures

- Reduced risk of injury during handling

Over years of use, the savings accumulate significantly.

5. Long-Term Resistance to Environmental Factors

Environmental exposure causes major wear and tear on traditional materials. UV rays, temperature changes, and moisture all contribute to accelerated material breakdown.

GRP Grating Offers Long-Term Environmental Protection

GRP Grating is specially engineered to withstand environmental extremes such as:

- UV exposure

- Heavy rain

- High temperatures

- Snow and ice

Thanks to its stable composition, GRP Grating does not:

- Crack

- Warp

- Fade

- Lose strength

This dramatically reduces the need for routine checks and fixes.

6. Non-Conductive Properties Reduce Electrical Maintenance

In areas where electrical conductivity poses a risk — such as electrical substations or industrial manufacturing sites — steel gratings require grounding systems.

GRP Grating Eliminates Conductivity Issues

Because GRP Grating is non-conductive, it reduces risks related to electrical shocks and eliminates the need for grounding hardware.

This saves money on:

- Grounding system installation

- Inspections

- Electrical safety maintenance

It also creates a safer work environment at no additional long-term cost.

7. Slip Resistance Lowers Accident-Related Maintenance Costs

Workplace accidents lead to downtime, medical costs, and damage to equipment. Slippery surfaces are one of the most common causes of industrial accidents.

GRP Grating Provides Built-In Slip Resistance

The textured surface of GRP Grating maintains exceptional traction even when wet or oily.

Advantages include:

- Fewer slip-related incidents

- Lower liability expenses

- Reduced equipment damage

- Improved worker safety

Safety improvements often directly translate to financial savings.

8. Fire-Retardant Options Reduce Fire Safety Maintenance

Fire safety regulations often require materials that resist ignition or reduce flame spread.

GRP Grating Meets Fire Safety Standards

Fire-retardant grades of GRP Grating meet multiple industrial certifications, reducing:

- Fire risk

- Insurance premiums

- Damage-related repair costs

This adds another layer of protection without additional ongoing expenses.

9. Resistant to Biological Growth

Traditional materials often require cleaning and treatment to prevent mold, algae, or bacterial growth.

GRP Grating Naturally Prevents Biological Contamination

Because GRP Grating does not absorb moisture, it does not support biological growth. This significantly reduces maintenance tasks such as:

- Pressure washing

- Anti-fungal coatings

- Mold inspections

Fewer cleaning cycles mean less time, water, and labor spent on maintenance.

10. Reduced Downtime Saves Operational Costs

Downtime is one of the most expensive consequences of maintenance work. When operations are interrupted to repair or replace materials, production efficiency drops.

GRP Grating Minimizes Downtime

With its long service life and infrequent maintenance needs, GRP Grating offers fewer disruptions. Components can be replaced quickly and are often designed for easy access.

This improves overall productivity while lowering long-term maintenance expenses.

Applications Where GRP Grating Maximizes Cost Savings

Some environments benefit more than others from the unique advantages of GRP Grating.

Ideal Industries

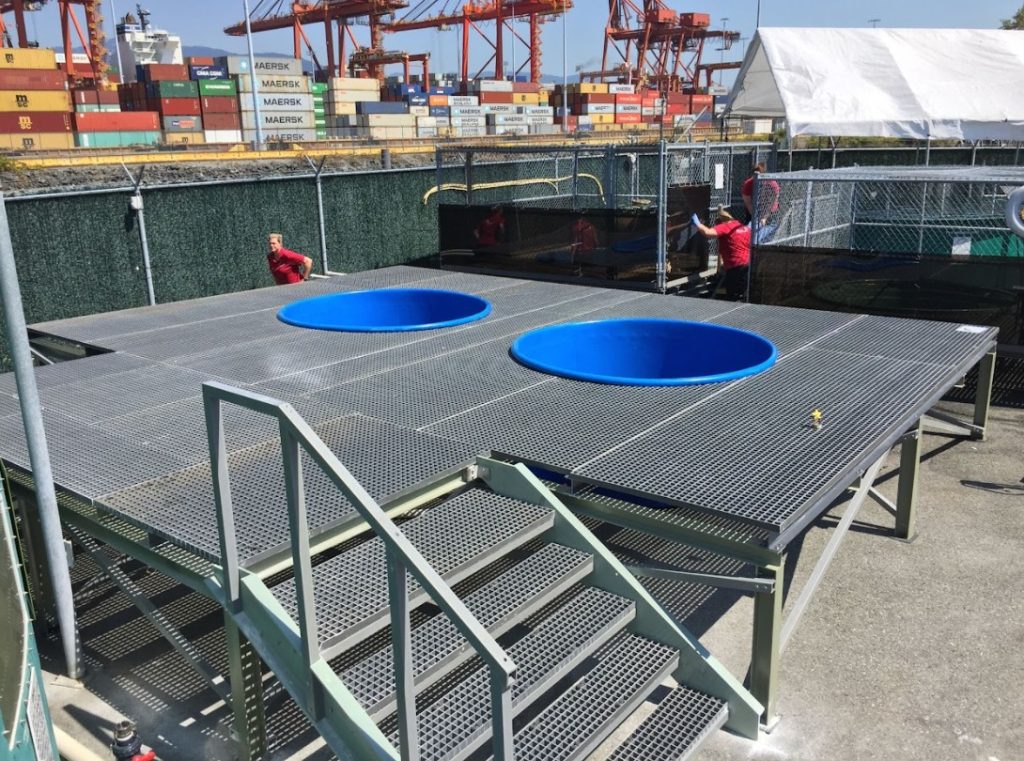

- Marine and offshore platforms

- Chemical plants

- Water treatment facilities

- Food processing units

- Power generation plants

- Oil and gas facilities

- Public infrastructure

- Poolside and leisure areas

In each of these environments, GRP Grating outperforms steel and wood by lowering lifetime maintenance costs dramatically.

Practical Tips for Getting the Most Value from GRP Grating

While GRP Grating requires minimal maintenance, a few simple practices ensure maximum lifespan.

Recommendations

- Conduct occasional visual inspections

- Clean surfaces periodically to remove debris

- Use proper load-bearing specifications during installation

- Select the appropriate resin type based on environmental exposure

These small steps help maintain excellent performance for decades.

Conclusion

GRP Grating is more than just a modern alternative to traditional materials — it is a long-term investment in durability, efficiency, and cost reduction. Its corrosion resistance, lightweight design, slip-resistant surface, fire-retardant options, and minimal maintenance needs make it one of the most cost-effective solutions available today. By choosing GRP Grating, industries reduce maintenance workloads, avoid expensive repairs, minimize downtime, and benefit from a product built to endure even the harshest environments. If your goal is lower maintenance expenses, improved safety, and long-lasting performance, GRP Grating stands out as the smart and economical choice.